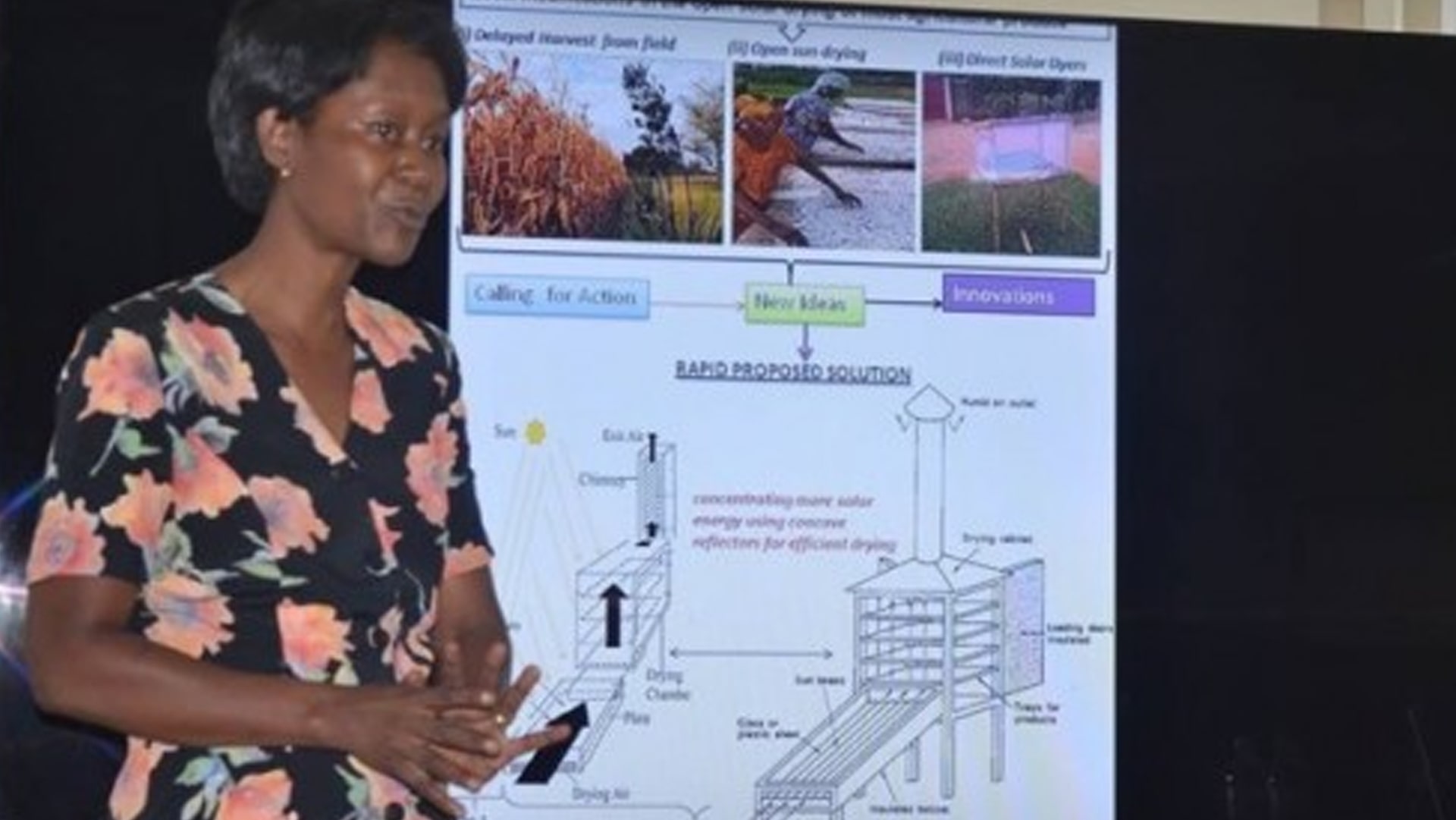

Brilliant ideas directed towards developing Ugandan powered Solar Dryers to serve sub-Saharan African communities and beyond

The 3rd RAN Innovation Monthly Garage was successfully held on Friday August 28, 2015 starting 3:00pm – 6:00pm at Makerere University School of Public Health ResilientAfrica Network (RAN) Innovation space. The interactive, knowledge creation and sharing opportunity attracted 33 participants. The garage hosted innovators of the RAPID Solar Agricultural produce Dryer under incubation in the Eastern Africa Resilience Innovation Lab http://www.ranlab.org/innovations/ric4ace-grantees. They are working on an improved solar drying Technology that will change current farmer reliance on direct sun-light for drying of produce in rural low income settings. The technology will make agricultural produce drying more efficient for different types of produce, reducing losses, aflatoxin contamination and drag.

The Problem

A third of the food produced in the world is lost or wasted according to Food and Agriculture Organization (FAO) representing a loss of 13 billion tons of food per year? Majority of this is estimated to be in sub Saharan Africa with significant volumes of food lost after harvest, the value of which is estimated at USD 4 billion for grains alone.

SOLAR energy usage in Uganda has gained momentum and results from the recently concluded community consultation exercise through Needfinding indicate that African communities are embracing the new technology in the Solar Dryer. According to the Electricity Regulatory Authority (ERA), Uganda’s energy development program will convey 30 Mega Watts of new solar power supply into the national grid by end of this year. One of the questions innovators who participated in the innovation garage answered was “As Innovators, what SOLAR opportunities can we harness to invent new Technologies for social change?”

Specific areas regarding the solar dryer discussed during this Garage session included:

- Design of different sizes of a Solar Dryer to fit the needs of different types of farmers

- Cost harmonization between large and small production for the dryer

- Security of the external Glass component (Concave Mirrors) on the Solar Dryer

- Exploring having different trays to dry different produce taking into account different products’ scent and durability of the Solar Dryer in-built components

- Mobility of the RAPID Solar Dryer (looking at the small house doors for in-house storage of the dryer)

- Copyright safety checks and

- Handling of Larger/bigger prototypes for bulk produce

Discussions

Moving forward, the Innovation Garage Participants explicitly brainstormed and came up with three different possible designs for prototyping. Participants were divided into three groups, they discussed and highlighted areas including but not limited to; how to control temperature and moisture within the Solar Dryer, cost harmonization, security with suggestions of caging the dryer or even casting the foundation to hold the dryer on concrete, fabrication of the drying trays to allow for drying of different produce taking care of scent and durability, documenting and learning from the comparative advantage between the currently used natural drying means and proposed solution, maintaining the quality of produce, options to regulate how much warm air flows into the dryer in variation to temperatures required for different produce being dried, assembling the solar dryer parts in-house, use wood as opposed to aluminum to build most of the solar dryer parts, install a small solar panel inside the dryer for uniform aeration. “We as a team have learnt so much from this garage session and are now comforted by the fact we know that there is this team of individuals who we can always reach out to in case of need as we work towards improving and prototyping this innovative idea” said Dr. Kulabako, the RAPID Solar Dryer Team Principal Investigator.

They also deliberated on the fact that farmers need to be informed about the available markets for all the dried produce and whether the Solar dryer could dry different produce at the same time without compromising quality of the produce, use of black material instead of glass, in-building square mesh around glass, explore automation of the solar dryer trays for industrialization among others.

The next steps are to prototype and simulate the proposed sketches in the Innovation Consortium Engineering Workshop in Kampala, Uganda. The Partnership with the Innovation Consortium Engineers provides a conducive environment where young Innovators receive mentorship and technical assistance from experts.

RAN is progressing well with efforts directed towards bringinging innovation to life and it just happens to be in the Garage, do not miss it! The Innovation Garage drives deep thinking by the attendees through brainstorm sessions, experimentation to pursue the best prototypes and solutions. All RAN events are open to multi-disciplinary persons because we realize that each discipline contributes significantly to the quality of the Innovation. Through this Garage, we hope to support local solutions that will transcend nations. We also hope to launch paradigm shifting Innovations that will change the way we conduct business. We would like to see Technologies developed in Africa being launched in the markets. The Innovation Garage is a great platform to support home grown solutions, we invite students, faculty, researchers, and community to come and be part of this radical group to invent game changing solutions.

We Look forward to the next prototyping session and yet another transforming brainstorm during the 4th RAN Innovation Garage scheduled September 25, 2015 starting 3:00 pm to 6:00pm EAT. Please do catch up with us in the next session and you can follow the conversation on #Innovation Garage.

Find more picture here